A Guide to Test Methods for Printed Circuit Boards

The last thing any designer wants to do is find out at the last minute that their product is flawed. All types of electronics, even if they are properly designed and carefully manufactured, are prone to problems. Many electronic products come out of the prototype stage with plenty of bugs and problems for designers to troubleshoot. However, if something isn't noticed before the product goes live, it can cause huge problems for the company.

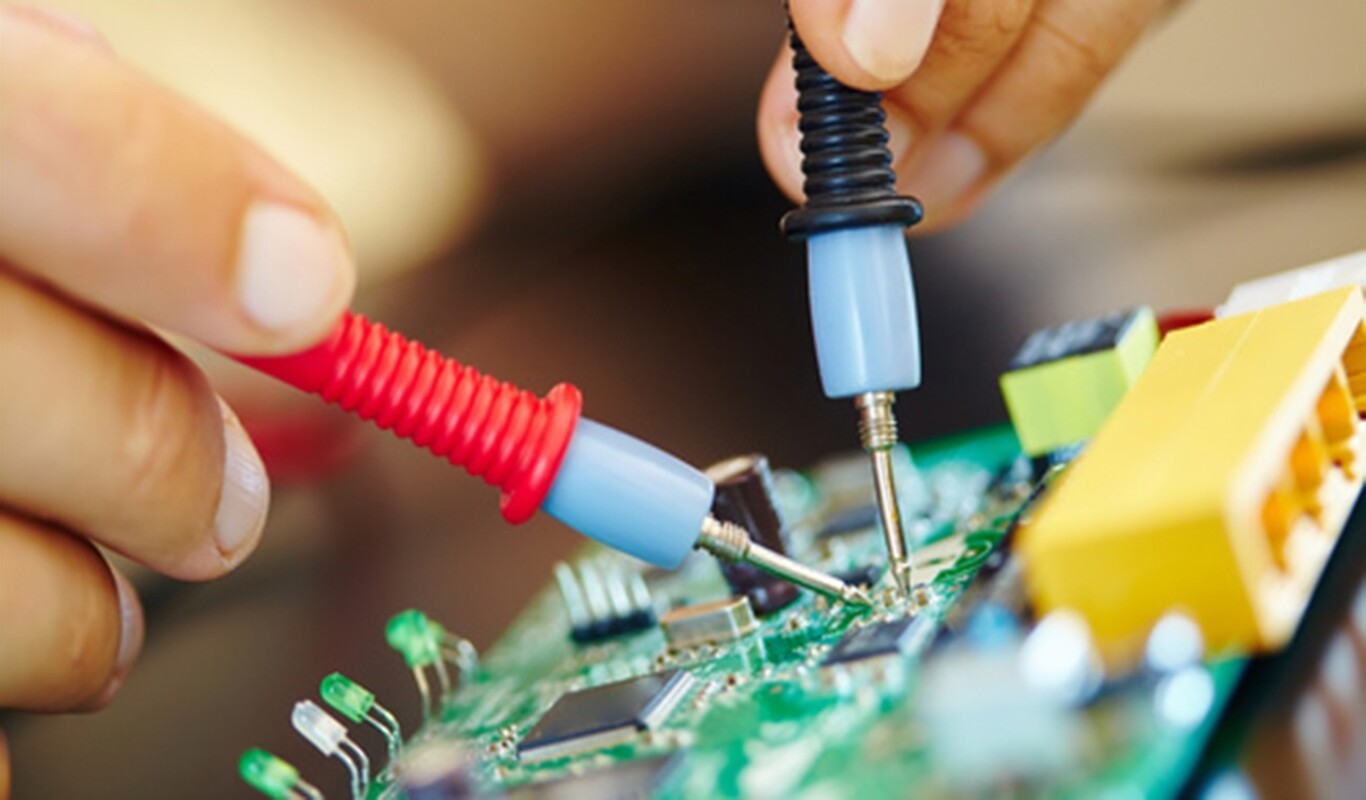

Testing electronics is very important, especially for printed circuit boards, as it prevents several problems. To gain a clearer understanding of how PCB testing can improve your PCB products, learn more about what PCB testing is and the main methods used to evaluate PCBs.

Benefits of PCB testing

Many companies consider PCB testing an absolute necessity because it offers them many advantages. Check out some of the key benefits of PCB testing below:

Error identification: The main benefit of PCB testing is that it helps identify problems in the PCB. Whether the problem is functional, manufacturable, or otherwise, PCB testing identifies issues in PCB design and layout so designers can make adjustments accordingly.

Time savings: In the long run, early-stage PCB testing helps save time, allowing designers to identify major issues during the prototyping stage. Comprehensive testing enables designers to quickly and easily determine the root cause of each issue and make adjustments so they can continue production at a faster pace and shorten product lead times.

Cost reduction: PCB testing prevents wasteful production of defective products by using prototypes and small-scale assemblies to test products. By completing thorough testing early in the design process, designers can prevent wasteful full assembly of defective PCBs, ensuring that the design is as flawless as possible before it goes into production. This step helps reduce production costs significantly.

Fewer returned products: When companies conduct PCB testing, they reduce their chances of selling defective products or products that do not meet performance standards. As a result, they don't see as many returned products, reducing the costs associated with refunding customers and disposing of defective items. In addition, fewer returned products can improve customer satisfaction and improve the company's reputation.

Increased safety: Because PCBs are often used in basic electronics, their failure can cause significant problems for a company's productivity or an organization's ability to perform essential services. Defective PCBs can cause fires that can put people nearby at risk. Pre-manufacturing testing also ensures that machines and workers are not damaged or injured by improper design during production.

While thorough testing of all types of PCBs is not required, especially those that mature in the product life cycle, most new PCB designs require robust and frequent testing of the design process. You can experience the benefits of PCB testing by establishing an appropriate PCB testing program for your organization's needs.

Types of PCB test methods

There are a variety of PCB test methods available, and no single method can solve all problems or meet every designer's requirements. Each test method should be carefully considered to determine whether it meets the specific needs of your manufacturing environment. Some factors to consider include the type of product you are testing, the problem you are testing for, and the reliability of your testing method. To give you an idea of the test methods available, we've summarized the key qualities of the four popular PCB test methods below:

1. Online test (ICT)

In-circuit testing is a popular PCB testing method favored by many PCB manufacturers and can find 98% of failures. This testing method uses special PCB testing procedures and equipment, including:

In-circuit tester: A tester system contains a matrix of hundreds or thousands of drivers and sensors that perform the measurements of the test.

Fixture: The fixture is connected to the in-circuit tester and is the component that directly interacts with the circuit board under test. This fixture looks like a bed of nails and is designed for the associated circuit board. Each "nail" or sensor point is connected to a relevant point on the test board, feeding information back to the tester. Fixtures are usually the most expensive part of the system.

Software: The software for the tester instructs the system on which tests to perform on each type of board under test, and indicates pass or fail parameters.

Using the ICT approach, manufacturers can test individual components and measure their performance regardless of other components connected to them. In general, this type of test is best suited for 3analog circuits, as it is best suited for measuring resistance, capacitance, and other analog metrics. Additionally, equipment costs mean that this test method is best suited for final testing of stable, high-volume products, rather than low-volume production or early testing phases where designs may change multiple times.

2. Fixtureless in-circuit test (FICT)/flying probe test

Fixtureless in-circuit test (FICT), also known as a flying probe test, is an ICT that operates without custom fixtures, reducing the overall cost of testing. First introduced in 1986, FICT uses a simple fixture to hold a circuit board while test pins are moved around and relevant points on it are tested using a software-controlled program. Since its introduction, FICT has been widely used throughout the electronics manufacturing industry due to its versatility.

The FICT test is used for the same things as traditional ICT, but because of the way it conducts the test, it offers different advantages and disadvantages. While FICT can be quickly, easily, and cost-effectively adapted to new boards with simple programming changes, it tends to be slower than traditional ICT. This quality makes it an ideal test method for low-volume production testing and prototype testing but is less efficient for large-scale production.

3. Functional circuit test

Functional circuit testing is exactly what it sounds like - it tests the functionality of the circuit. This type of testing is always done at the end of the manufacturing program, using a functional tester to check that the finished PCB meets specifications.

Some answers to frequently asked questions about functional circuit testing and how it works can be found below:

How do functional testers work? There are many types of functional testers, but generally share the same functionality - they simulate the final environment in which the PCB should operate. Functional testers typically connect to the PCB through their test probe points or edge connectors and conduct tests to demonstrate that the PCB functions to design specifications.

Is the functional circuit the same as ICT? In some ways, functional circuit tests are similar to ICT in that they use connectors to connect to the circuit board. In the case of functional circuit testers, they use pogo pin devices to connect to the PCB and generally require fewer pins than ICT fixtures. The test device then runs the program to test the PCB to ensure that the device operates exactly as expected.

When is functional circuit testing performed? As mentioned earlier, functional circuit testing is the last type of testing done in a PCB manufacturing plan to ensure that the product is performing according to specifications.

What does functional circuit testing evaluate? Typically, functional circuit testing simply looks at the functionality of a product as a whole and scores it on a pass or fail basis. Therefore, it is not an ideal testing method for early prototypes as it cannot identify details of product issues.

4. Boundary-scan test

Boundary-scan testing looks at the lines on the PCB and is widely used as a method of testing integrated circuits when all nodes of the circuit cannot be reached. In this type of test, batteries are placed in leads from the silicon die to external pins to test the functionality of the board.

The biggest difference with this type of test is its ability to evaluate the board without reaching all its nodes. This quality is important for evaluating integrated circuits with multiple layers and high densities, as these types of PCBs have become more common in recent years.

In fact, this test method is very versatile and can be used for a variety of applications, including functions such as system-level testing, memory testing, flash programming, and central processing unit (CPU) emulation. It is often used in field service to detect problems in functional systems.

No matter which method you use, PCB testing is an essential step in the design process, helping you save a lot of time and money by preventing errors before they affect your production. However, to successfully run tests on your PCBs, you need a trusted supplier to ensure your prototypes are built to order every time. If you want to customize the PCB board, welcome to contact us.

Singo is a professional custom PCB board manufacturer. Some of our products are often required to operate in harsh environments where quality and reliability are paramount. With years of experience, we have won a good reputation among customers in the field of electronic production with reasonable prices, abundant resources, and on-time delivery.