Singo is a full-service PCB assembly company, so you have our team available throughout the conceptualization stage and to a successful product launch. Our priority is delivering a high standard of work with quick turnaround times in everything we do for you. Our advanced equipment and skilled engineers perform a multitude of electronic manufacturing services, completing short-run productions of up to 10,000 units at a time.

Home / All / PCB Manufacturing /

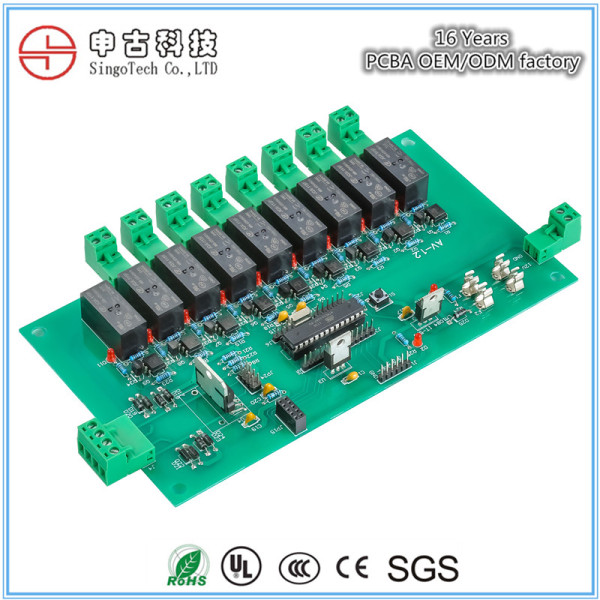

PCB assembly manufacturer in China with over 16 years of experience.

Do you need any help?

We can help you find what you want! Talk to our sales team members and benefit from their expert advice

- Tel

- *Title

- *Content

PCB assembly manufacturer in China with over 16 years of experience.

| Categories | PCB Manufacturing |

|---|---|

| Brand | Singo PCB Assembly and Manufacturing Services |

| Model | Rigid PCB |

| Terms of Payment | Western Union, T/T |

| Update Time | Apr 25,2025 |

Detail Information

PCB assembly manufacturer in China with over 16 years of experience.

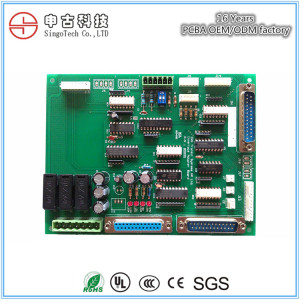

Widely used, rigid PCBs are made up of a solid substrate material, which ensure that the circuit board isn’t distorted. Ranging from single layer PCBs to multi layered ones, rigid PCBs are beneficial where they need to be set in shape and maintained during the lifetime of the equipment. Their compact size and easy maintenance make them ideal for use in a wide range of applications where the components need to be fixed and where there is application stress as well as increased temperatures.

At SINGO, we offer you high-quality rigid PCBs to meet your bespoke requirements.

SPECIFICATIONS OF RIGID CIRCUIT BOARDS MANUFACTURING

Rigid PCB Application

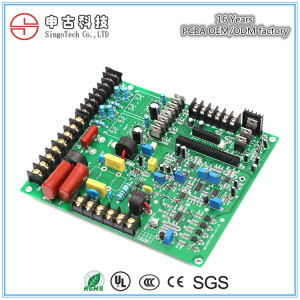

1) Industrial Automation and Electronics

We can use a rigid board for supporting hardcore industrial applications. So, we can use a multilayer PCB to create buried connections and providing controlled impedance. Additionally, we can use them in applications that involve high frequency, high power, and high voltage. Some prominent examples include automation in robotic arms, conveyor belts, pressure controllers, gas tank monitors, and temperature controllers.

2) Medical Applications

We can also use them in a wide range of medical applications. However, they have restricted use in this sector as we only use them in large equipment. Some prominent examples include EMG (electromyography) equipment, tomography machines, and MRI systems.

3) Aerospace Applications

The aerospace sector is known for its extreme environment and conditions. Some of the major challenges include high temperature, friction, and high pressure. So, in this case, rigid circuit boards are very beneficial. This is because we can design them with premium substrates and superior laminates. Some prominent examples include cockpit equipment, temperature sensors, control mechanisms, routing equipment, dashboard instrumentation, black box equipment, etc.

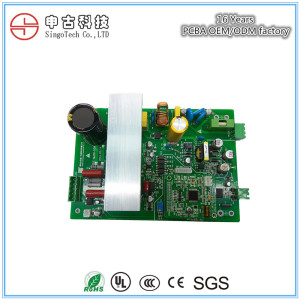

4) Automotive Applications

We can see an intensive use of rigid circuit boards in automobiles. We have to deal with extreme conditions when it comes to vehicles. So, we tend to rely on rigid circuit boards because they have lamination. This lamination can protect them from the high amount of heat generated by the engine. Additionally, we can also use a rigid printed circuit board in the dashboard of the vehicle and as an AC/DC power converter. They are also very useful as transmission units, junction boxes, electronic computer units, and power distributors.

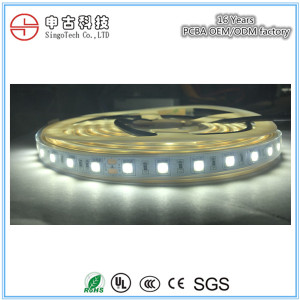

PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility. Examples include Automotive headlights, Airport runway landing lights, Lighting used in military field applications, Street lighting, Highway tunnel lighting, Photovoltaic (solar) lighting, Flashlights and lanterns, Traffic and signal lighting, Lighting in hospital operating rooms, High growth plant lighting and many others.

Singo ADVANTAGE AS A Rigid PCB MANUFACTURER

At SINGO, we have more than16 years of experience in fabricating and assembling a wide variety of PCBs- from rigid, Flex to rigid-flex PCBs. Irrespective of how easy or complex your requirement is, our state-of-the-art equipment and team of experts is well-equipped to handle it. When you join hands with us you also get access to a rich body of industry best practices that give you an edge.

We are extremely committed to offering quick turnaround times that help you go-to-market early. The fact that we offer prototype quantities to large production runs with the same unstinting focus on quality, endears us to our clients. You can count on us for turnkey services as well and rest assured that you will get high quality products.

All you need to do is to get in touch with our team and share your bespoke requirements. Our experienced team will share a custom quote and ensure that the PCB is fabricated to your exact needs.

All of this at the most cost-effective prices that ensure that your project is extremely competitive!

Rigid PCB FAQs

1. What is a rigid PCB?

Rigid PCBs are made up of a solid substrate material, which ensure that the circuit board isn’t distorted. Ranging from single layer PCBs to multi layered ones, rigid PCBs are beneficial where they need to be set in shape and maintained during the lifetime of the equipment.

2. Why do rigid PCBs find wide application?

Their compact size and easy maintenance make them ideal for use in a wide range of applications where the components need to be fixed and where there is application stress as well as increased temperatures.

3. What is the difference between rigid and flex PCBs?

The most notable difference between rigid PCBs and flex PCBs is that rigid PCBs are inflexible, while flex PCBs can be bent or otherwise shaped.

4. What are some of the factors that go into the choice of Rigid vs Flexible PCBs?

Some of the factors include:Durability;Bend areas;Cost;Design sophistication

5. What then is a rigid-flex PCB?

A rigid-flex PCB combines the flexibility of flexible circuits with the durability of a rigid PCB.

6. Do you take orders for prototype quantities for rigid PCBs?

Yes, absolutely. Whether you are looking at rigid PCBs or full production runs, we have you covered.

7. Do you cater to different surface finishes with rigid PCBs?

Yes, we cater to a wide range of surface finishes.

8. Do you offer multi layers rigid PCBs?

Yes, whether you need single sided, double sided or multilayered boards, we have you covered.

9. How long have you been in the business of designing PCBs?

We have over 15 years of experience in dealing with different varieties of PCBs. Our state-of-the-art equipment and team of experts offer significant advantages.

10. Can we count on you for quality?

We have robust quality check procedures in place. Above everything, a large portfolio of satisfied clients stand as the biggest testimony to our success.

Review

- Loading...

Related Products

Do you need any help?

We can help you find what you want! Talk to our sales team members and benefit from their expert advice

- Tel

- *Title

- *Content